Once upon a time, in a bustling city where coffee shops were aplenty and tech startups sprouted like mushrooms after rain, lived a group of sharp-minded individuals. They were not your ordinary bunch; they were the masterminds behind cutting-edge technology that seemed like magic to most. Among their many achievements, predictive modeling in supply chains was their magnum opus. This technology promised to change the game for businesses around the globe — a crystal ball of sorts for the logistics world. And thus began the adventure of transforming chaos into calculated precision.

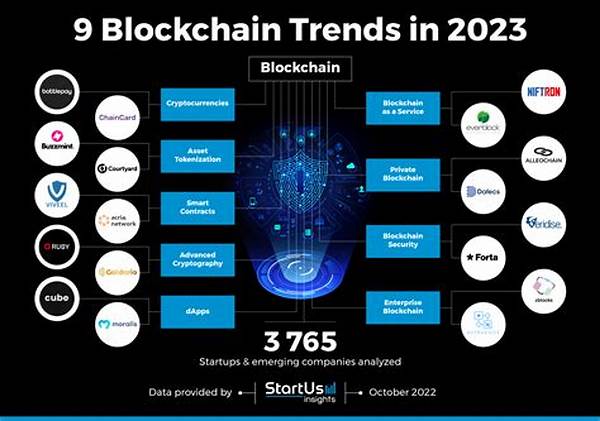

Read Now : Advanced Blockchain Techniques For Developers

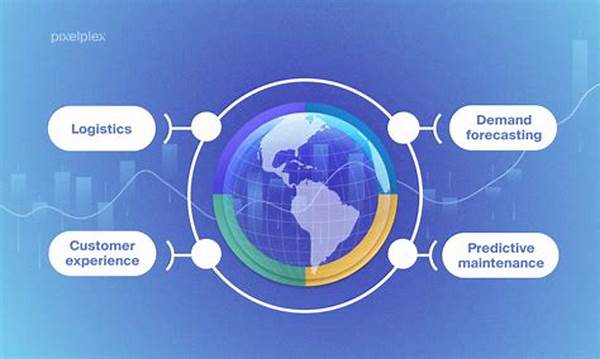

Why Predictive Modeling in Supply Chains Matter

Picture this: You’re a logistics manager sipping your morning latte, scrolling through your endless emails. Suddenly, your worst nightmare begins—unexpected delays due to a supply chain hiccup. But, wait! Here comes predictive modeling in supply chains to the rescue. Imagine having the power to predict these hiccups before they happen. These models take into account thousands of data points, forecasting potential pitfalls and helping you strategize plans before the chaos even starts. Like a superhero find in a plot twist, predictive modeling saves businesses from stumbling blocks, ensuring a smooth ride through the rough terrains of logistics.

With this tool in your arsenal, you’re not just surviving but thriving. It’s like getting a traffic update before you hit the road—knowing what to expect makes all the difference. So next time you face the ever-changing dynamics of supply chains, remember that predictive modeling isn’t just a tech term; it’s your roadmap to a future that’s not just predictable but conquerable.

Benefits of Predictive Modeling in Supply Chains

1. Dodging the Unexpected: Ever waited for a package that just wouldn’t show up? Forecasting demand with predictive modeling in supply chains helps avert those pesky surprises.

2. Smoothing Operations: Consider it a spa day for your supply chain—predictive modeling helps ensure everything flows seamlessly.

3. Better Decision-making: Information is power, peeps! Having insights into potential trends lets you make data-driven decisions like a boss.

4. Cost Efficiency: Save the big bucks by optimizing routes and reducing wastage. Predictive modeling in supply chains is your financial advisor on steroids.

5. Agility Boost: Stay light on your feet. With predictive modeling, you’re ready to pivot and adapt faster than ever to whatever comes your way.

Real-Life Applications of Predictive Modeling in Supply Chains

You might be wondering, “Where does this cool tech actually play out?” In the fast-paced world of fashion, predictive modeling in supply chains helps brands keep up with seasonal trends, ensuring the hottest jacket of the season is always in stock. Elsewhere, in the world of electronics, it aids companies in not just meeting demand but anticipating it—cutting down on excess inventory like a ninja with their incredible foresight.

And it’s not just about keeping stock ready. It’s about delivering that stock on time, every time. The food industry too, benefits by forecasting shelf life and managing perishables like a pro since nothing’s worse than a mushy apple or stale bread. Predictive modeling in supply chains turns what used to be a logistical nightmare into a well-choreographed ballet, efficiently keeping up with the intricate dance of supply and demand.

Challenges and Solutions in Predictive Modeling in Supply Chains

1. Data Overload: The ocean of data can be overwhelming. Streamline processes to sift through noise and focus on the gems.

2. Accuracy is Key: Gotta have the best data for best results. Garbage in, garbage out—it’s the golden rule.

3. Integration Woes: Old meets new—sometimes merging new tech with legacy systems is like fitting a round peg in a square hole. Seamless integration is the name of the game.

4. Training Needs: Everybody needs some good ol’ training to keep up with the tech evolution. Even the coolest dude needs to learn to surf before hitting the waves.

Read Now : Blockchain Fintech Conference In Europe

5. Staying Updated: Technology changes at the speed of light, and keeping up can feel like running a marathon. Regular updates are your hydration breaks on this tech journey.

6. Pitfalls of Prediction: Sometimes predictions fail; it’s not an exact science. But hey, even superheroes have their off days.

7. Investment Costs: Initial setups could be pricey, so it’s like buying the fanciest gear—worth it in the long haul.

8. Security Concerns: Data breaches are scary. Strong cybersecurity can protect your data and maintain trust.

9. Dependency Dilemma: Rely too much, and the tech becomes the puppet master. Balance is key.

10. Constant Monitoring: Keep an eye on things—like a personal trainer for your supply chain, ensuring everything runs in top shape.

The Future of Predictive Modeling in Supply Chains

As technology continues to evolve, the capabilities of predictive modeling in supply chains are set to expand even further. Think AI and machine learning pairing up like your favorite duo, constantly learning and adapting to the ever-changing world of logistics. This future isn’t just about creating more sophisticated models but about integrating them into every aspect of supply chain management, from sourcing to delivery, in a seamlessly interconnected web of efficiency.

Expect drones flying around with instant deliveries and automated systems predicting demands down to individual preferences, personalizing the supply chain experience to a level never seen before. It’s not science fiction; it’s where we’re heading—where predictive modeling in supply chains isn’t just a tool but a ubiquitous presence in every part of our logistical lives. So, buckle up, because the future is not only going to be efficient but also incredibly exciting!

Embracing Predictive Modeling in Supply Chains

As we draw this discussion to a close, it’s clear that predictive modeling in supply chains is not just a fleeting trend. It’s a paradigm shift, transforming the way businesses operate, moving from reactive to proactive measures. For businesses ready to embrace this change, the rewards are vast—enhanced efficiency, reduced costs, and the ability to outmaneuver competition with ease.

The call to action, my friend, is simple: don’t get left behind in the dust of the past. Step into the brave new world of predictive modeling, where your supply chain is not a mystery to be feared but a puzzle to be mastered. Keep learning, adapting, and evolving, because this story is just beginning, and the narrative is yours to shape with every prediction that comes true.