Once upon a time, in a bustling city filled with thriving businesses, there was a little company called “FutureFlow Inc.” They were growing fast, but something was holding them back. Their supply chain was as unpredictable as the weather. The owners knew they needed a hero, a strategy that would save the day. Enter: supply chain forecast optimization methods, the shining knight to tame the chaos and bring harmony to the realm of purchase orders and stock levels.

Read Now : Blockchain-based Property Transaction Systems

Why Supply Chain Forecast Optimization Matters

Let’s face it: without a solid plan, supply chains can become a logistical nightmare. The team at FutureFlow Inc. was facing a crisis; products were either overflowing in their warehouse or nowhere to be found when customers needed them. They needed supply chain forecast optimization methods like fish needed water. These methods could balance the delicate art of demand and supply, avoiding wastage and shortages alike. Simply put, it was all about predicting the future with style and precision—a bit like being the coolest fortune teller in town!

So, what did these magic methods involve? Basically, it was a mix of data, tech, and a sprinkle of wizardry. It started with analyzing past sales, current trends, and potential disruptions. With all this info in hand, the forecasting became as sleek and predictable as your favorite Netflix series. Overnight, FutureFlow Inc. could see the future more clearly and plan their inventories with confidence. Suddenly, those endless stock piles were under control and their business became a well-oiled machine.

Top Techniques in Forecast Optimization

1. Historical Data Juggling: Imagine sifting through piles of past sales data to spot patterns. These supply chain forecast optimization methods are like a detective’s playbook but way cooler!

2. Tech Wizardry: AI and machine learning are the digital wands that bring forecasting magic to life. These supply chain forecast optimization methods take number-crunching to another dimension.

3. Demand Sensing Skills: It’s like having a sixth sense for market trends. With these supply chain forecast optimization methods, you can almost see the future shifting before your eyes.

4. Collaboration Charms: Teamwork makes the supply chain dream work. Sharing insights across departments becomes a breeze with these killer supply chain forecast optimization methods.

5. Scenario Sorcery: Running “what-if” scenarios is like having a backup plan to a backup plan. These supply chain forecast optimization methods let you stay ten steps ahead of any crisis.

The Impact of Proper Forecasting

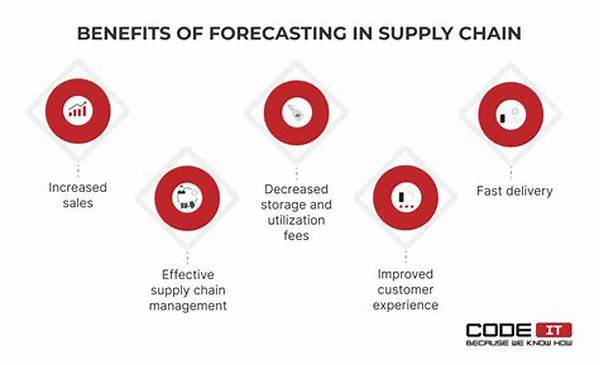

What happens when supply chain forecast optimization methods are executed perfectly? Let me paint you a picture: imagine a warehouse that feels alive, with stocks that move like a well-choreographed dance recital. There’s this rhythm in operations—a fluid flow that makes delays, stock-outs, and wastage turn into yesterday’s news. Orders are fulfilled in record time, and customers? They’re grinning ear to ear because they get what they want, when they want it.

You see, it’s like giving your business x-ray vision into the future. Decisions on inventory become smarter. Costs? Reduced significantly. Profits start to rise, and before you know it, every corner of the company feels the positive ripple effect. It’s the magic of supply chain forecast optimization methods, a little secret sauce that transforms a business’ operations from zero to hero.

Common Challenges in the Supply Chain World

Reality check: It’s not always smooth sailing with supply chain forecast optimization methods. Picture this, even with the sharpest tools, the world might still throw a curveball. Maybe it’s a sudden change in consumer tastes or an unexpected global event blocking your supply lines. Flexibility becomes your best friend.

In these moments, the methods need a backup—like when your GPS goes rogue, and you need to rely on old-school maps. Successful supply chain forecasting doesn’t just rely on the data; it requires that “gut feeling,” the ability to pivot at the last second, and yes, sometimes just plain luck.

So, what’s the takeaway? Embrace the challenge, keep refining the tools, and remember that every hiccup is a chance to learn and grow. With supply chain forecast optimization methods, you’re not just preparing for the future; you’re dancing with it.

Key Terms Explained in the Forecasting Game

Alright, knowing the lingo is half the battle. Supply chain forecast optimization methods come with their own glossary:

1. Lead Time: The time it takes from ordering a product to its delivery. It’s the supply chain heartbeat.

2. Safety Stock: Extra inventory to avoid stockouts during a demand surge. It’s your supply chain’s security blanket.

Read Now : Reducing Fraud In Property Dealings

3. Demand Planning: Anticipating customer demand to align production. It’s like playing chess, but cooler.

4. Inventory Turnover: How quickly products sell and get restocked. It’s the ultimate metric for efficiency.

5. Backorder: Orders that can’t be fulfilled on time. Not something you want in your supply chain diary.

6. Bullwhip Effect: Demand forecast errors causing big inventory swings. Think of it as your worst kinda mood swing.

7. E-commerce Integration: Bridging online sales data with supply forecasting. It’s the future, now.

8. Supplier Co-op: Partnering with suppliers to streamline forecasts. It’s like bringing more brains to the brainstorm.

9. Real-time Analytics: Live data to make instant decisions. Think of it as your superpower eye for detail.

10. Data Visualization: Making numbers look actionable and palatable. It turns data into delicious eye-candy.

Embracing the Future of Forecasting

So here’s the scoop—supply chain forecast optimization methods are like the band behind any superstar business performance. They’re not always in the spotlight, yet without them, there’d be chaos. Companies embracing these methods find themselves not just prepared but ahead, ready to turn challenges into opportunities.

In a world where innovation is key, these methods are not just good-to-have, they are the secret formula. A business can stay afloat with traditional methods, but if you’re dreaming of scaling heights and setting trends, these forecast optimization methods are your magic carpet.

Remember FutureFlow Inc.? They used these methods to transform from a small local biz to a global powerhouse, with each step calculated, thanks to the perfect supply chain forecast strategy. Who’s to say your story won’t be next?

Closing Thoughts

Dude, those are the basics of what’s up with supply chain forecast optimization methods. They turn the risky business of supply chains into a smooth operator. It’s like seeing through the fog and knowing exactly what’s going to happen. Companies dig this, and everyone wants a piece of it.

So, if you’re in the game, start taking notes, because this is the future—an uninterrupted flow of goods, a dance with time and resource that’s as exhilarating as a high-speed chase scene. Roll with these methods and watch as your supply chain becomes the polished diamond in your business crown.